The cement sector in Pakistan continues to evolve amid increasing construction demand and financial fluctuations.

This short article gives an in-depth examine cement fee nowadays in Pakistan, selling price comparisons with past months, components influencing the marketplace, and trends throughout a variety of regions. Whether you are a builder, contractor, or homeowner, knowledge cement price tag in Pakistan is essential for budgeting and job arranging.

What Are The present Costs?

Exactly what is the Cement Charge in Pakistan?

The cement rate in Pakistan ranges from PKR one,two hundred to PKR 1,four hundred per fifty kg bag. This price may perhaps fluctuate based on the cement model, location, and transportation charges. Significant city facilities including Karachi, Lahore, and Islamabad usually knowledge slightly increased prices on account of logistical fees and better desire for cement.

In this article’s a quick overview of common price ranges:

Brand Value for each fifty kg Bag (PKR)

Blessed Cement one,280

DG Cement 1,250

Fauji Cement 1,230

Maple Leaf Cement 1,270

Dewan Cement 1,200

What Aspects Affect The present Cement Fees?

Several aspects impacting cement charges Perform a task:

Gas & Strength Expenditures: Cement producing is Electrical power-intense. Fluctuations in oil and fuel prices directly impact the price of cement in Pakistan.

Raw Material Availability: Key components such as gypsum, clinker, and limestone have become costlier, influencing the expense of cement.

Seasonal Demand from customers: All through peak design months (spring and summertime), cement desire surges, elevating rates.

Currency Trade Fee: Imported raw supplies become dearer if the rupee weakens in opposition to the dollar.

Governing administration Procedures: Duties, taxes, and import regulations also effects the cement fee right now in Pakistan.

These components collectively determine how cement selling prices shift thirty day period by month throughout Pakistan.

Cement Value in Pakistan: Comprehending the industry Developments

Exactly what are the most recent Cement Prices in Pakistan?

The newest cement costs in Pakistan change among PKR one,200 and PKR one,four hundred per bag, affected from the manufacturer, distance from generation models, and local offer chains. Cement brands in Pakistan like Fortunate Cement, DG Cement, and Fauji Cement manage steady high-quality, which often justifies their high quality pricing.

Exactly what are the Predictions for Cement Costs within the Impending Months?

The cement industry in Pakistan is expected to remain stressed from world fuel rates and inflation. Analysts forecast that cement fees might boost a little or remain steady in coming months Except if sizeable changes take place in gas tariffs or raw content Value dynamics.

Components which will impact future pricing:

Publish-election economic reforms

Fuel subsidy policies

Global commodity costs

A stabilization or reduction in fuel prices could lead to lower prices due to reduced production and logistics costs.

So how exactly cement rate in pakistan does Desire Have an impact on the Price of Cement in Pakistan?

Need for cement peaks throughout Lively development seasons, for example March by means of September. In the course of these periods, cement premiums in Pakistan may possibly climb as a result of restricted source and enhanced orders. Conversely, off-period months can see stabilized or somewhat lessened charges.

Big infrastructure and housing initiatives underway across metropolitan areas like Lahore, Islamabad, and Karachi carry on to add to robust cement demand from customers, pushing the market towards greater premiums.

Forms of Cement Accessible in Pakistan: Which Should really You select?

Exactly what are the Different Types of Cement Readily available in Pakistan?

Pakistan provides A selection of cement types catering to varied design tasks:

Standard Portland Cement (OPC): The most commonly utilised variety of cement for standard structures.

Portland Pozzolana Cement (PPC): Presents enhanced durability and resistance to chemical attacks.

Slag Cement: Manufactured using blast furnace slag, ideal for industrial structures.

White Cement: Aesthetic cement Utilized in tiles, flooring, and decoration.

Hydraulic Cement: Promptly sets when blended with water, ideal for drinking water-retaining constructions.

A lot of these cement provide unique roles, and picking out the ideal 1 is dependent upon development desires, environmental disorders, and desired strength ranges.

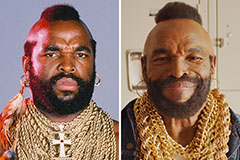

Mr. T Then & Now!

Mr. T Then & Now! Rick Moranis Then & Now!

Rick Moranis Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now!